- Home

- Products

- Mid Drive motor

- Mid Drive Kit

- Battery

- Application

- Support

- About us

- Contact us

full-dimensional quality verification from parts to components

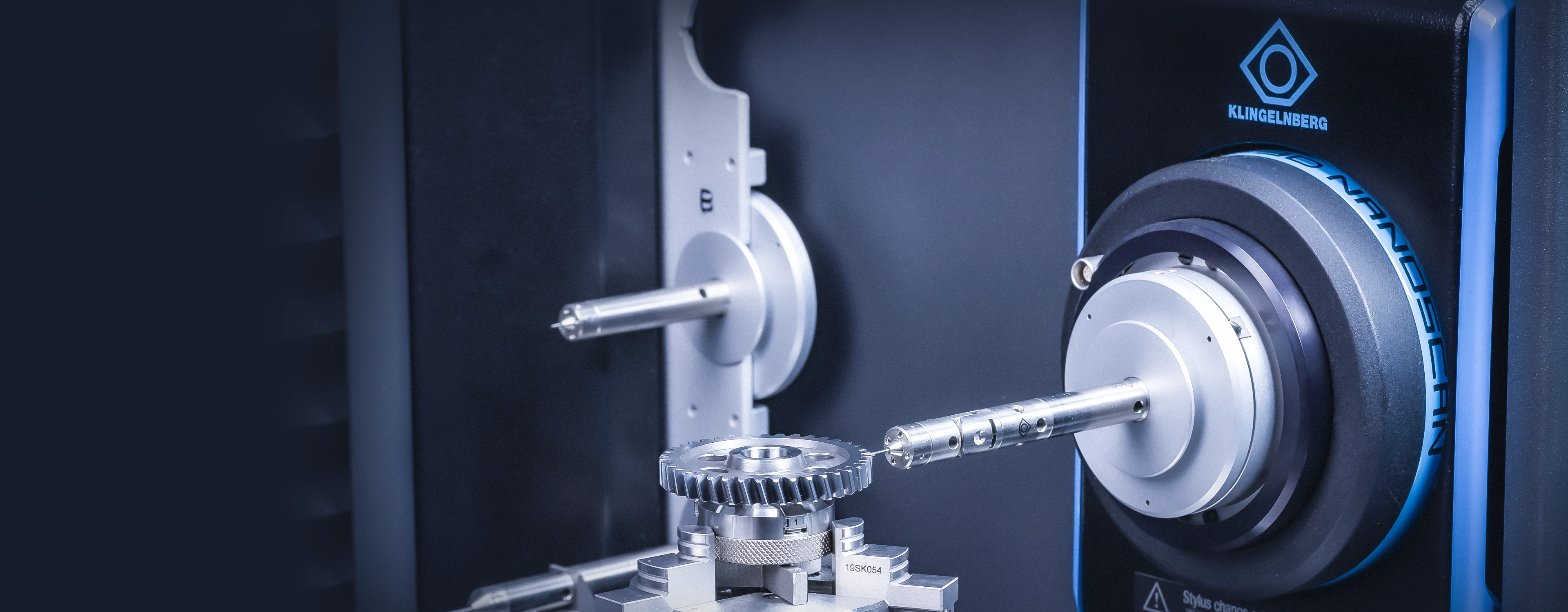

We have an intelligent control laboratory, a reliability laboratory, and an EMC laboratory. We are equipped with advanced testing equipment such as the Danish B&K PULSE noise spectrum analysis system, the German Zeiss CT, the German Zeiss coordinate measuring machine, and the Klingelnberg gear testing center, as well as universal material testing machines, gear bending fatigue testing benches, material friction testing benches, and worm gear transmission efficiency testing benches. The lead screw drive efficiency test bench and other testing equipment undergo a series of rigorous tests including reliability, vibration, shock, dust-proof, water-proof, and EMC, comprehensively ensuring product quality.

EMC test

IP67 water resistance test

Low-temperature test

High temperature test

Noise Test

Fatigue resistance test of parts

CCD Test

Air Tightness Test

Utilizing advanced equipment including Klingelnberg gear testers and ZEISS CT inspection centers, PREETO conducts comprehensive precision inspections on gear components. This includes tooth profile and flank measurement, internal porosity analysis, dynamic tooth impact resistance testing, static tooth strength analysis, and fatigue strength analysis. This multi-dimensional approach creates a complete inspection system covering both appearance and performance. Standardized inspection procedures ensure process consistency, preventing defects at the source and providing reliable assurance of gear quality.

Rotor: Undergoes 100% dynamic balancing testing to precisely calibrate eccentricity, ensuring smooth, vibration-free operation.Stator: Subjected to dual verification through precise inter-winding resistance measurement and high-voltage insulation testing, guaranteeing safe and reliable electrical performance. The overmolded stator process creates a seamless, sealed structure, boosting heat dissipation efficiency and enhancing overall protection. These combined processes enable stable operation under sustained high-power conditions, comprehensively improve overall performance.

PREETO implements a dual-stage precision solder joint inspection system:

1.First Stage: Utilizes high-resolution X-ray imaging for non-destructive internal inspection of solder joints, accurately identifying hidden defects such as cold solder joints and voids.

2.Second Stage (Pre-encapsulation AOI): Employs automated optical inspection (AOI) systems to perform a full scan of solder joint appearance, checking for shape, size, and surface oxidation.

These complementary inspection methods achieve comprehensive control over solder joints, from internal quality to external integrity, effectively reducing PCBA soldering defect rates and providing solid quality assurance.

From individual components (gears, gearboxes, motors, and PCBAs) to fully assembled units, PREETO conducts over 200 performance tests. Additionally, extensive aging tests lasting up to 5,000 hours simulate extreme usage scenarios like high temperature, high humidity, and vibration to validate product durability and stability. This end-to-end quality control fortifies user safety and the long-term stable operation of the equipment.

Inquiry